Compact, Efficient,

and Economical

Screening

Compact, Efficient,

and Economical

Screening

OVERVIEW

OVERVIEW

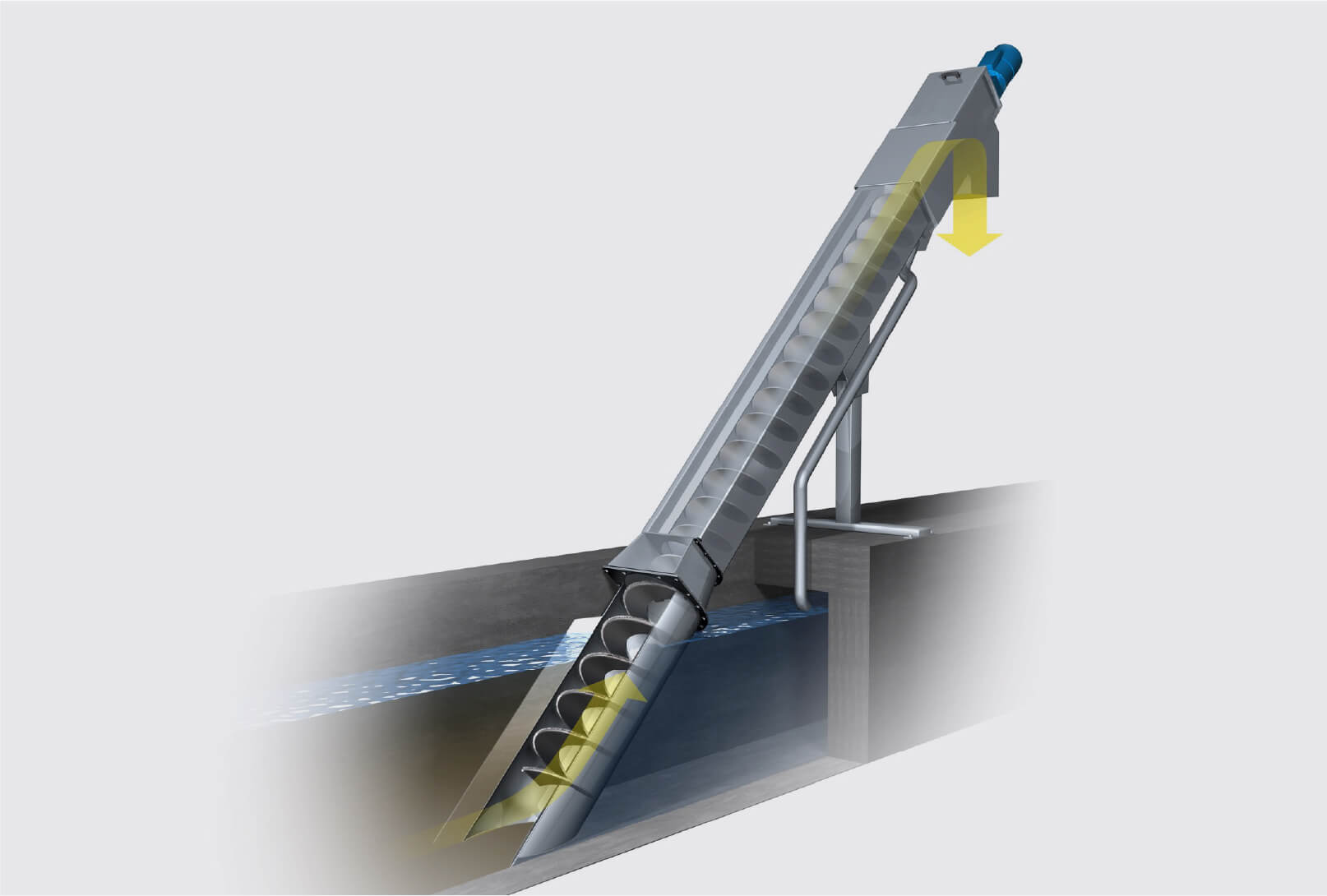

SSS Spiral Screw Screen

The SSS Spiral Screw Screen is a compact and economical screen for the removal, dewatering, washing, and transport of screenings. It is ideal for small treatment facilities looking for an economical and high performing headworks solution. Available screen openings range from 3mm to 6mm diameter perforations. The captured screenings are washed, compacted, and dewatered before being discharged. The model is customized for the flow of the plant and the plant civil structure requirements. U-troughs with removable covers facilitate maintenance and cleaning while also including a high-quality liner for long life and low noise.

PRODUCTS

PRODUCTS

PRODUCTS

PRODUCTS

PRODUCTS

Features and Benefits

- Compact construction with cost-saving design

- Model customized for the flow and structure

- Screens, washes, and compacts in a single unit.

- Can be installed in steel tanks

- Low operating costs

- Service-friendly design

- All stainless steel construction (304 or 316)