Primary Screening

Solutions

Primary Screening

Solutions

OVERVIEW

OVERVIEW

Wastewater Treatment and Management

The first step of municipal sewage treatment at any treatment plant begins with the headworks screens. Screening is the first and most critical step in the primary treatment of municipal wastewater with various other processes to follow. If the primary screening is less than effective, the remaining processes suffer, and the plant does not efficiently or economically produce acceptable effluent. CleanTek can provide well proven and effective primary screening solutions through use of either the Roto-Sieve Drum Screen, SSS Spiral Screw Screen, or the PTU Complete Plant. We also offer screening handling products such as shaftless screw presses, conveyors, and piston presses to provide a complete screening headworks solution.

Primary Screening Products

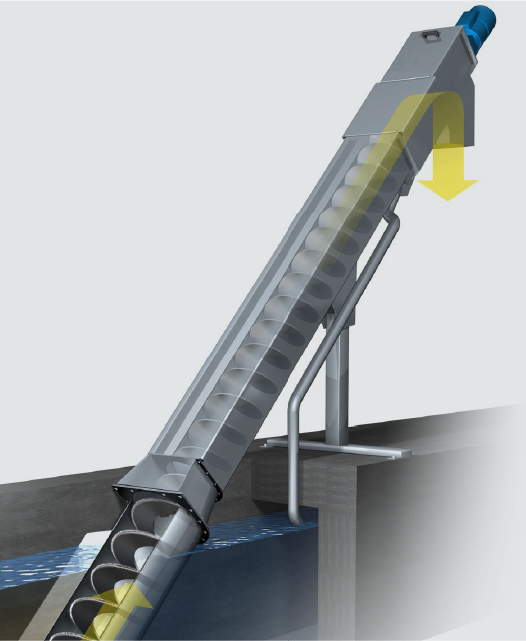

The SSS Spiral Screw Screen is a compact and economical in-channel screen for the removal, dewatering, washing, and transport of screenings. It is ideal for small treatment facilities looking for an economical and high performing in-channel headworks solution. Available screen openings range from 3mm to 6mm diameter perforations. The captured screenings are washed, compacted, and dewatered before being discharged. The model is customized for the flow of the plant and the plant civil structure requirements.

The Roto-Sieve Drum Screen is an internally-fed, self-cleaning, inclined drum screen. With over 5000 units installed globally, the Roto-Sieve has unsurpassed quality, reliability, and performance in the marketplace. Roto-Sieve Drum Screens are a well proven, effective, and economical method to provide fine or coarse screening in a municipal application. With high operational reliability, a long service life, and low energy consumption, Roto-Sieve rotary drum screens are an excellent long-term investment.

Screenings discharged from Roto-Sieve screens can be further dewatered and compacted using the Shaftless Screw Press. The press captures the screenings straight from the drum screen and compacts, dewaters, and transports the screenings.

If transportation is the only concern for the screenings, the use of our Shaftless Screw Conveyor fits the job. The conveyor optimally transports screenings to another location that typically houses a larger wastebin.

The PTU Complete Plant is a completely sealed plug-and-play compact headworks unit, available in various capacities ranging from 0.2 MGD to 4.5 MGD. It combines screening, grit removal, and sometimes FOG removal into one self-contained unit. The design of the unit is customized according to customer requirements and is manufactured in 316 stainless steel. The PTU is mostly suitable for smaller plants or when customers need a compact headworks solution as the result of space limitations.