Achieving your

Wastewater Management

Objectives

Achieving your

Wastewater Management

Objectives

OVERVIEW

OVERVIEW

Municipal Applications

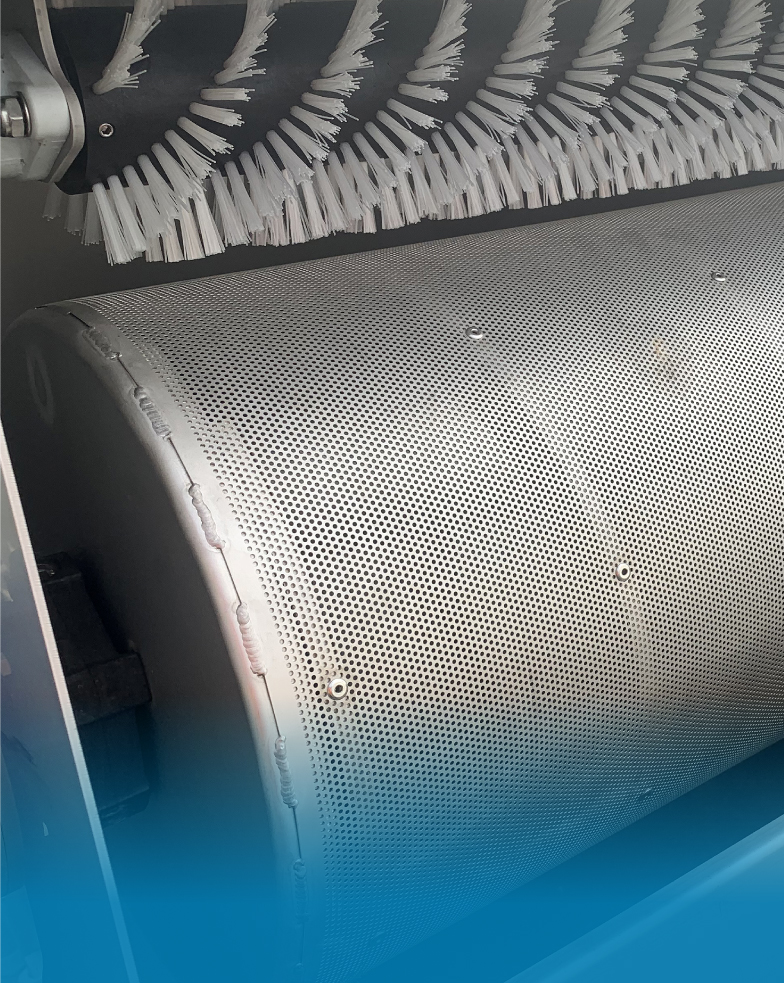

Cleantek Water Solutions supplies a wide range of cutting-edge, well proven, and economical solutions for municipal wastewater treatment. These range from fine screening for protection of MBR systems to septage receiving to energy recovery from sludge. With thousands of installations both around the world and in the United States, Cleantek provides industry-leading equipment for the municipal wastewater industry. With a wide variety of equipment, Cleantek can offer an efficient, reliable, and effective solution for a range of applications.

APPLICATIONS

APPLICATIONS

APPLICATIONS

SOLUTIONS

SOLUTIONS