Roto-Sieve Unsurpassed

Quality, Reliability, and

Performance

Roto-Sieve Unsurpassed

Quality, Reliability, and

Performance

OVERVIEW

OVERVIEW

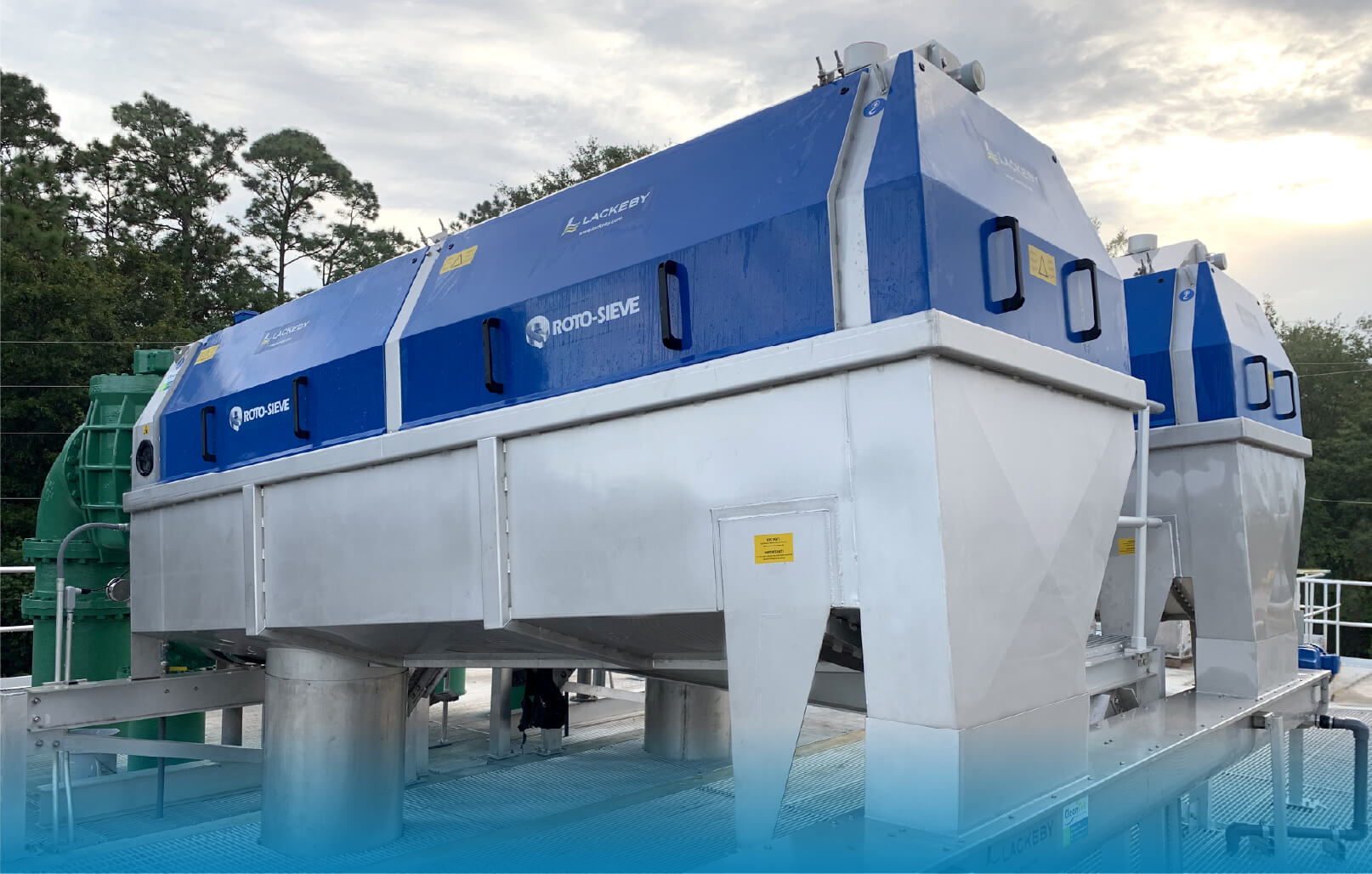

Roto-Sieve Rotary Drum Screens

The Roto-Sieve rotary drum screen is an internally-fed, self-cleaning, inclined drum screen. With over 5000 units installed globally, the Roto-Sieve has unsurpassed quality, reliability, and performance in the marketplace.

In municipal wastewater treatment applications, the Roto-Sieve rotary drum screen is renowned as a fine screen to protect MBR systems; for primary treatment; and for various sludge screening applications.

Industrial users, such as poultry processors, meat processors, food processors, breweries/wineries, and recyclers, utilize it for not only wastewater treatment but also product processing. The Roto-Sieve rotary drum screen can be effectively used in almost any application where a solid needs to be separated from a liquid.

With high operational reliability, a long service life, and low energy consumption, Roto-Sieve rotary drum screens are an excellent long-term investment. The Roto-Sieve has undergone continual improvements and today it represents the most advanced internally-fed rotary drum screen available. The innovative drive system on our larger models requires no trunnion wheels and minimal lubrication which significantly lowers maintenance while also improving operational reliability. Due to its internal feed and circular perforations, Roto-Sieve rotary drum screen offers the best separation that can be achieved mechanically. Perforated opening sizes range from 0.6mm to 6mm diameter and capacities from 0.2 MGD to nearly 10 MGD.

PRODUCTS

PRODUCTS

PRODUCTS

PRODUCTS

PRODUCTS

Roto-Sieve Drum Screens

RS-11

RS-22

RS-24

RS-36

RS-48

RS-412

RS-416

Features and Benefits

No Trunnion Wheels

The innovative drive design and lack of trunnion wheels results in very low maintenance and high reliability.

Low Energy Usage

Even our largest 10 MGD models utilize only a single 1.5 hp motor.

Very Low Maintenance Requirements

The lowest maintenance requirements in the industry today.

Low Spray Water Usage

Friction-driven rotating cleaner brush results in very low spray water usage. Up to a 90% reduction in spray wash usage over designs utilizing continuous spray wash systems.

Overflow Protection

The automatic overflow bypass system with an overflow sensor and alarm protects sensitive downstream processes such as membranes from damage.

Reliability

Over 5000 proven installations around the world. Almost 50 years of experience in the drum screen market.

No Seals

No vertical or slotted seals of any kind eliminates the risk of pass-through or seal failure.

Small Footprint

High capacity and high capture rate with a small footprint. Very few civil requirements.

Versatility

Useful in many different municipal and industrial applications..

Application Flexibility

Small units for small systems/low flows and large units that have up to a 10 MGD capacity per screen.