Meet your Challenges

Head On with Our Proven

Solutions

Meet your Challenges

Head On with Our Proven

Solutions

OVERVIEW

OVERVIEW

Trusted Products

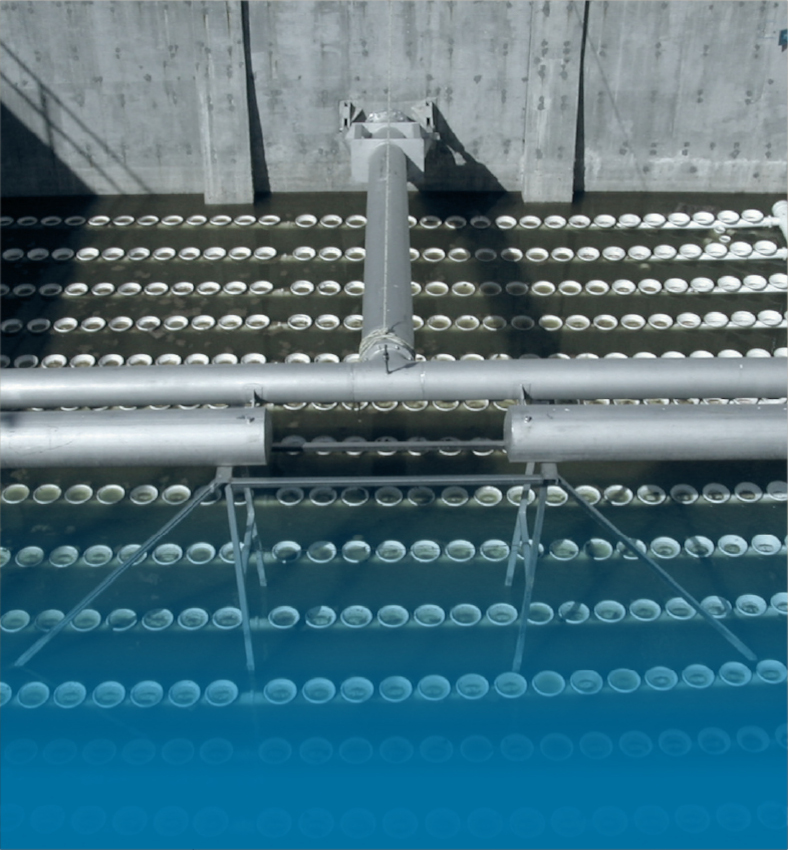

To help customers achieve their process water or wastewater treatment objectives, Cleantek offers a well-proven and high performing line of screening, dewatering, and energy recovery equipment. All of our products are supported by hundreds of different installations, providing us with extensive and unmatched expertise in many different municipal and industrial applications.

PRODUCTS

PRODUCTS

PRODUCTS

SYSTEMS

SYSTEMS